We will use cookies to ensure that we give you the best experience on our website. If you accept, that means you agree to our use of Cookies and Privacy Policy. Learn more

Leapers Attends Addy Machinery’s Spring Open House

Note: All quotes in this article are recorded from an interview with David Ding, May 13, 2024.

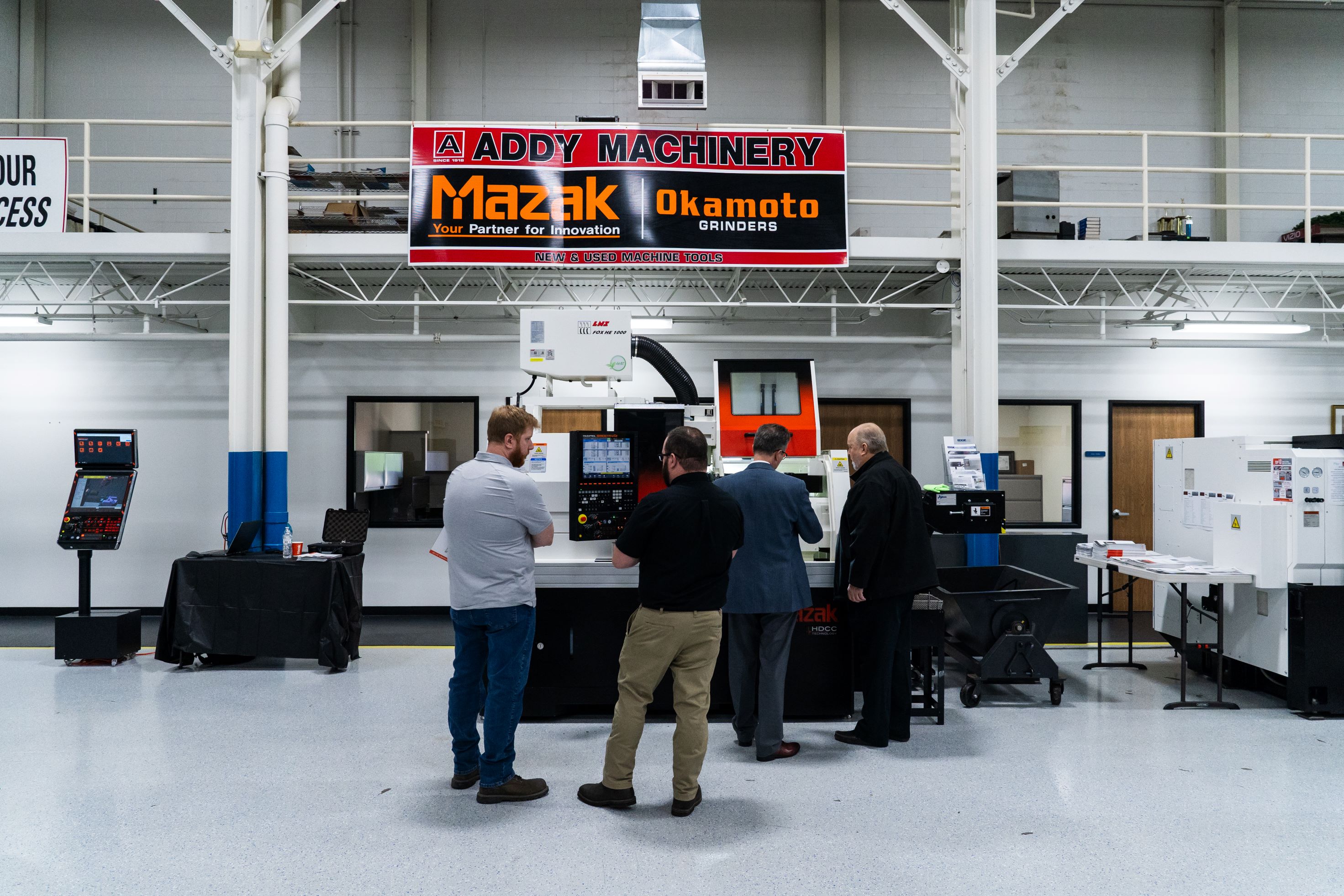

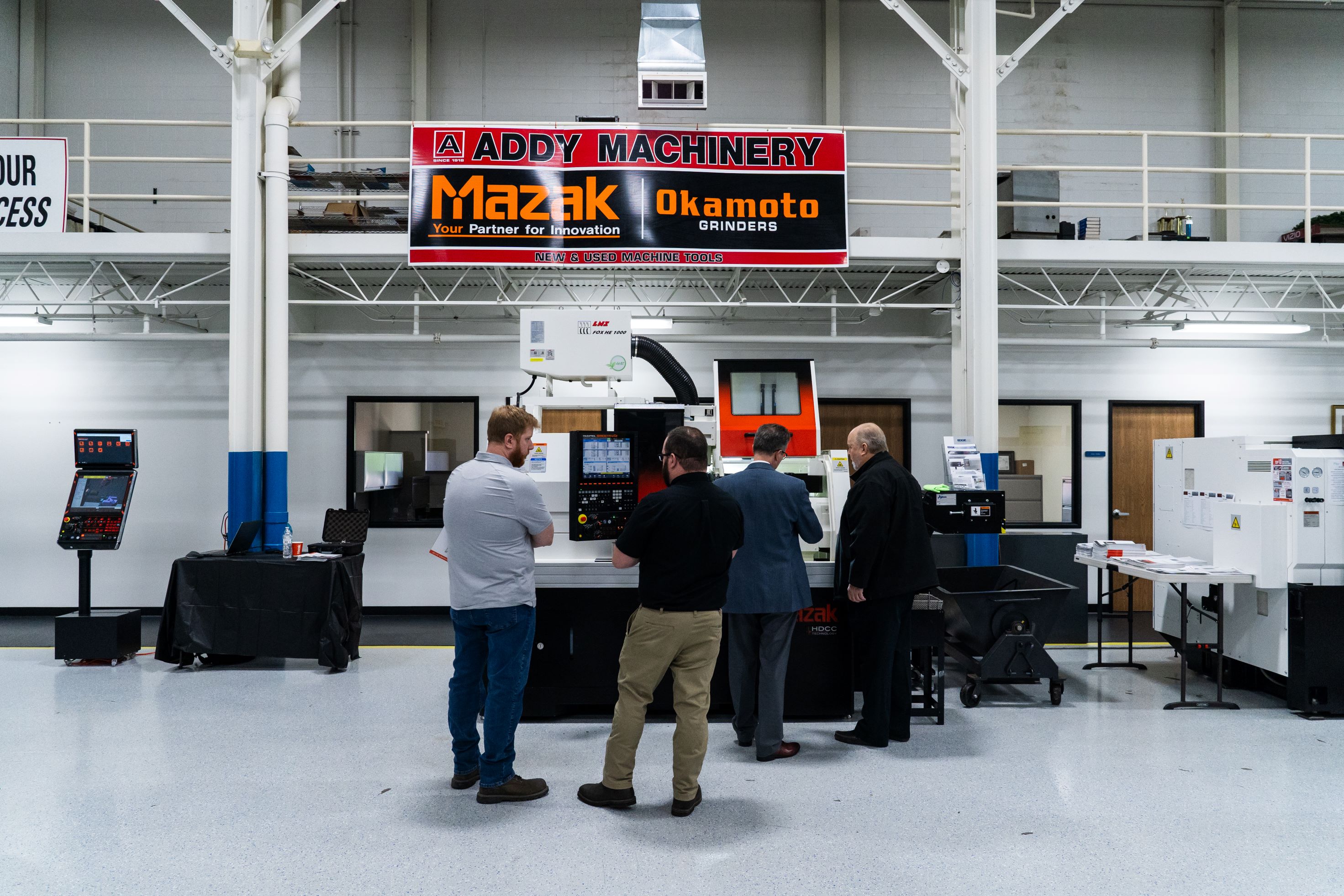

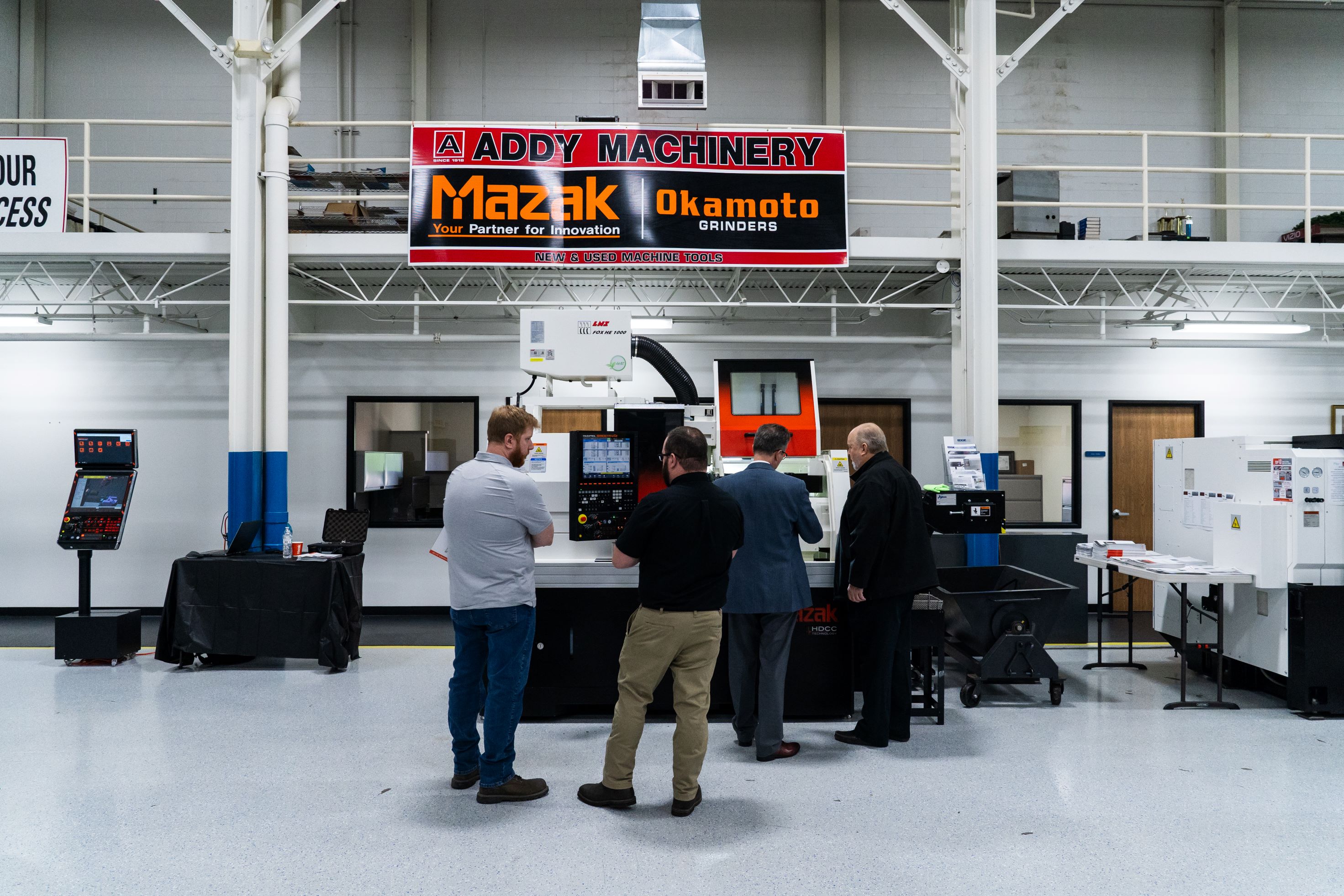

It was an honor to be invited to Addy Machinery's Spring Open House held at their Eastern location in Clinton Township, Michigan last week May 8th and 9th. Attending the event were manufacturing companies and clients from all over, with the main attraction on Wednesday being a keynote direct from Dan Janka, President of Mazak U.S.A. Quite a few Mazak machines were working on display, including a Mazak Integrex i-450H S (for those machining nerds).

But before I get deeper into the event, I’ll take the opportunity to transport us back in time…

Why Invest in U.S. Manufacturing?

Steve Addy of Addy Machinery and David, the CEO of Leapers, first met 15 years ago around 2009. This a year after the financial crisis of 2007 and 2009, when David Ding dreamed of building up manufacturing operations here in the U.S. The Lehman Brothers had declared bankruptcy and many people – consumer or commercial – couldn’t pay back their loans as property owners. In Livonia Michigan, almost everywhere you drove by had buildings for sale. At least 30 to 40% of the industrial neighborhood around Leapers’ headquarters today was on sale, going bankrupt, or being put up for public auction. Companies had been outsourcing manufacturing overseas since the 90’s and 2000’s and China was paradise for manufacturing and cheap labor. Trends would not shift to bringing manufacturing back to the U.S. until the Trump era almost 10 years later, when trade deficits and China’s rapid growth in technology would spur contingency plans by the business world.

Given all this, I asked David: “So why invest in manufacturing in the U.S. at that time?” He said:

From day one, I felt strongly for small businesses. I have to know how I build my products. My operation depends on pushing these products out to distributors.

But you always have this concern: Who is making this for you? How is this being made? And: how am I going to control what I want it to do?

If you don’t have your own manufacturing, that means you always have to negotiate with your sourcing partners. They can be good and nice, but you also see the potential of risk. Everyone wants to do more business and at a certain point your partner won’t be able to satisfy your finances, volume, or needs. The other thing is, you won’t have the foundation. You’ll have the ideas, you’ll get things made, you’ll sell them. How will you do this continuously, with generations of products?

Many people in the early 2000s believed and treated manufacturing as a liability because you need to do additional operations in addition to your business, you need to deal with the workers, all of that. But I truly believe in a very integrated operation. And I also see how all overseas partners, when they grow big, their mentality of expanding the business [takes over]. People could be very wild during those times.

This isn’t 5 years or 10 years to me. I want to see that this can keep growing. By working at Ford Motor Company and studying history, seeing the transformation of outsourcing – I can see it’s risky. I told myself, when I am able to I am going to get into manufacturing. In the early 2000’s I started overseas but very quickly, within 5 years’ time frame, I said, I need to do this in the U.S.

Manufacturing in the U.S. and building a foundation for Leapers represented more than just a business decision. In his past life David was a police officer in Taiwan and head of his precinct. After completing his service he immigrated to the U.S. in pursuit of a graduate degree and worked for Ford Motor Company before founding his own company, Leapers, in 1992. By then, America and the possibilities it represented had become a part of him and how he viewed the future of his family.

When asked again, Why the U.S.? David said:

Because I treat the U.S. as my hometown. It’s a true belief. My daughter was born here and my future is in the U.S. If I were to be just another trader or importer, that wouldn’t give me that comfort-feeling of roots, of having something that can be grown with your own technology. No manufacturing means no roots. To me, that’s very important.

Leapers Begins Building U.S. Manufacturing

David had been thinking about investing in manufacturing in Michigan throughout the recession and by 2009 he decided to take action. When David sets his eyes on something he does it with conviction. He recruited a Director of Manufacturing with decades of industry experience running $5-10 million dollar level operations. By July 2009 he drafted a floorplan and had secured a team to make the renovations. By August the work was complete, and Leapers made its first purchase of six brand new Haas machines.

In the beginning the learning curve was steep. Leapers would spend upwards of $50,000 just to build a fixture to run the machine. We had yet to develop the ability to build fixtures ourselves – the way we do today. We needed to hire highly skilled precision fixture builders, and the cost was significant. The operation grew machine by machine, person by person, and we kept our eyes set on building deep in-house manufacturing knowledge to become entirely self-reliant.

A year later in 2010 Leapers was already looking beyond Haas. We knew that the best machines in terms of precision, quality, and production level were Mazak. The Mazak distributor was Steve Addy. So we started interacting.

For the businesspeople counting dollars and cents, they would say it doesn’t make sense to use Mazak to make firearm parts – but [that’s] not true. The most important thing is to challenge yourself to create leverage, learn, and create your competitive advantage. Every business must have your own model to do that.

Addy Machinery is a complete machine tool distributor serving Michigan's metal working industry since 1918, and it's where Leapers sourced all 16 of the Mazak machines on our UTG PRO production floor in Livonia, Michigan. We purchased our first Mazak machines from Addy in 2010: one lathe and one horizontal. From there Leapers bought a new Mazak every 1 to 2 years. Today we are the proud owner and operator of 14 Mazak HCN-4000 Horizontal machines, an Integrex 150, a QTS-200 lathe machine, and 2 fully integrated Palletech automation systems, all from Mazak.

David says the negotiation was the most fun with Steve Addy. I wish I could have been a fly on the wall back then.

He would say, let’s do $350K. I’d say, Well I can start with 250. He would say, No, no, it’s impossible! I’d say Okay I can go up a little bit, let’s say a $60K difference from asking. He would pretend to call up headquarters and he would call up people, the president of Mazak, this and that, and we would negotiate. It was always very professional.

I always liked to say this: You need to make your money, but I am a small business. I need your support to make manufacturing happen in the USA! It was very colorful, very dramatic. We did great business together and Steve is very good – he provides the best service.

Mazak on Manufacturing Today

During the open house at Addy Machinery, the other attendees and I had the opportunity to listen to the President of Mazak USA, Dan Janka, give an illuminating presentation. Dan heads the U.S. branch for Mazak headquartered in Florence, Kentucky, operating hand-in-hand with Mazak Japan.

Dan talked about a few different topics: an overview of Mazak today, an economic and market summary, ending with emerging technologies for the manufacturing industry. Mazak first came to the U.S. in 1968 from Nagoya, Japan, and commenced full U.S. production in Florence by 1981. They’ve expanded to 8 technology centers and 5 technical centers in North America, with 11 Mazak factories globally. They’ve relentlessly invested in owning and controlling their operations, knowing that downtime means financial losses for companies in manufacturing, committing to world-class servicing and hitting KPIs like 95% next day spindle replacement or 98% same day shipping for certain parts. Mazak wants your working capital to be spent on your operation rather than the purchase and storage of spare parts.

One of the biggest themes of the day was about multi-tasking and automation: robots, cobots, and applied AI to increase the productivity of your machine operators. The U.S. and especially the manufacturing industry is experiencing a shortage of skilled labor due to the aging of Boomers and coming up of Millennials and Gen Z, who work differently and hold higher expectations at the same time. Outside of the age we’re in, manufacturing in the U.S. has always been higher cost than outsourcing to other countries. Thus increases our urgency to improve automation and increase efficiency and capacity while using less workers overall. A huge challenge to manufacturers trying to implement advanced automation is the learning curve. Mazak continues to invest in improved operator interfaces so that manufacturers can get off the ground without being deep-learning coding gurus.

Leapers and Manufacturing Automation

All this information helped me put Leapers’ manufacturing journey into even greater context. Leapers made the decision to invest in a large capacity, world-class manufacturing center in Michigan almost a decade before politics and corporate began to shift manufacturing back to the U.S. instead of outsourcing overseas.

Leapers first installed our Mazak Palletech automation systems in 2012, a full decade before it has become an emerging theme of conversation in 2024. Each Palletec has 32 tombstones inside to house different product fixtures and complete multiple operations once parts are loaded. The Palletec system allows the manufacturer to increase leverage on a single machine, machining multiple different product lines with preinstalled fixture setups, programming, and scheduling. Imagine you have a single spindle: you would be working on 2 tombstones at a time for a given part with multiple operations to complete machining. To switch products or change the line, you’d need a day or two to recall the system, re-setup, program and calibrate for repeatable precision. Now, it’s instant. This type of automation allows us to reduce manual handling, increase precision, and create efficiencies using one machine to machine multiple parts. But you also need higher skillsets, better operations management, and optimization calculations to make the system work to your advantage.

Nowadays automation comes in many forms, from full-on robots and AI to cobots that cohabitate the space with the operator and take care of easy repeatable processes. It takes forward thinking, investment of money and time, and willingness to fail for the sake of more sustainable future operations to make the leap.

To Our Partnership with Addy Machinery and Mazak

We can’t thank Steve and the Addy team enough for inviting us to participate in their open house last week. It was incredibly rewarding to meet everyone from Mazak and show them all the cool parts and products we make on their machines. We pride ourselves on the continual advancement, optimization and scale of production, and cleanliness of our shop floor, and none of it would be possible without the Addy’s and Mazak supporting our U.S. operations. More to come as we continue engaging with the hunting and shooting community as well as the manufacturing community here in Michigan.

Kevin Jin, esteemed Director of our U.S. UTG PRO Manufacturing center, likes to say that Steve Addy is the best salesperson he’s ever met. If we look at the Mazak machines populating our floor, there’s no denying that… After this Wednesday, I now have my own experience meeting Steve. It put a smile on my face to watch him open the Leapers 2024 catalog to page 6 with pride. There lies a full page spread of our Mazaks lined up row by row operating in production. Steve would leave the catalog open to that photo on our display and run up to people to show them what their machines can do with pride.

I can’t think of a more suited marriage than that between Mazak and Leapers. So much of Leapers’ DNA is about being fully horizontally and vertically integrated: from the breadth of products and solutions across shooting platforms, to the depth of developing the manufacturing knowledge, capabilities, and technology to own our product development lifecycle end-to-end. I heard Steve Addy describe it as a “mini Mazak philosophy,” being a “fully integrated vertical operation.”

Pictured Left to Right: Michael Addy, Steve Addy, David Ding, Margaret Ding, Nick Addy, Giovanni Pantalena

Pictured Left to Right: Margaret Ding, Daniel Janka, David Ding, Steve Addy

With that, I leave you with a few words of inspiration from David:

Once you set a direction, never deviate. Just keep working on it until you are good, until you are better – and then keep working on it. That’s why The Best Never Rest.

There’s a lot of takeaways I could glean from this type of steadfast, at times blind, often going against the tide, conviction. Seeing Leapers grow and advance the products it designs and manufactures over 31 years, I start to see the edges of David’s vision.

This is why manufacturing is important. It’s not building for the now. It allows you to build for generations.